Region's largest homebuilder lands a whopper: 32 acres in Woodinville

Comments

-

I’ve gotta interview GC’s this coming week. Worst year ever to remodel. Oh well.RaceBannon said:

Lot of truth hereRatherBeBrewing said:creepycoug said:

Bingo.RaceBannon said:No yard and 2 feet from your side neighbors

All the rage with the cost of development these days

I may be headed back to that area myself and looking for a little space. There are a lot of older places on nice lots. You can always fix up the house; you can't expand your lot (usually).

I’ve had to explain this concept to my significant other repeatedly. I’m not entirely against a subdivision but the newest ones are an exercise in how close and cheaply you can build houses and get away with it. She is starting to grasp that it may be better to get something non cookie cutter with a bit of space, and put some sweat equity into it.

We are in the market for an upgrade. Our current house is in the range of ones that shot up 20% in a quarter and are going like hot cakes the day they’re listed; the ones that are a step or two higher haven’t increased as much yet so I’m trying to strike while it makes sense.

It seems there are only three options:

1. Nice, newer houses with the accoutrements one expects: open floor plans, big kitchen, impressive master, walk-ins, bathrooms that don’t remind me of airplanes, etc.

Unless you hit the seven figure price point those will be built on a 7,000 SF lot and you can have a conversation with half of the neighborhood from your postage sized backyard.

2. A custom built from 1970-2000 something before the McMansion subdivision made that rare. It will be on primo land, instead of flat farm land that has been turned into a generic grid or something next to a busy four lane road.

The downside is that it will often be some crazy shit, most likely dated beyond hope and the architect who designed and drafted it with his own three hands was institutionalized for hearing voices.

Enjoy this three bedroom, eight bathroom, with staircases inspired by MC Escher! Features wine cellar that can be converted to a sex dungeon (or vice versa), three bars, dedicated RV parking for a 98 foot RV or a dirigible, dining room built in a Japanese style, the adjoining living room with a Southwestern flair and a fireplace made out of the bones of a now extinct wild horse! We suggest you learn to use the fireplace because this house uses more electricity than a small African nation. No windows on the north side of the house but there are impossible to replace skylights throughout. New owner assumes all responsibility, including possible haunting by malevolent spirits.

3. The “Grandma’s been put in the cheapest old folks home we could find and we’re splitting this jackpot seven ways” special.

House will look even worse because it’s filled with 1970s furniture, curtains, peeling linoleum, flowery wallpapers, the worst and shaggiest carpet you can imagine, toilets and baths will be pink. When this house was built it wasn’t allowed to have more than one small window per room, they will all be too high or too low to create the perfect atmosphere of mid century gloom. The kitchen is wide enough for one petite person to be in at a time.

I hope you really like oak or something that looks like oak! Because everything in this house looks like fucking oak. The window trim and sills, every door, every cabinet, maybe a wall or two. Everything is oak! Except for the floors, which are carcinogenic plastics.

The yard is the perfect size and will look great if it’s not neglected for another 30 years. When your neighbors are doing some domestic violence shit or yelling at their new puppy you won’t know because your $850k house isn’t three feet from theirs!

The problem is the shitty homes are overpriced limiting how much to light on fire remodeling it and still getting a return. If that matters which it usually does

You could take any house to the studs that is on a nice lot and build it back better (SWIDT). If you hire a good GC you can get it done fast. But its 100 grand easy. Or you could call @1to392831weretaken and spread it out over years of pain and suffering

As a contractor I always say there is nothing we can't do with your money

I like to say that -

This for the kitchen? At least there's not a lot of lumber involved in that. The main problem with a lot of other materials isn't so much the cost but the wait. Eight weeks for a bathroom vanity. We got our bedroom carpet in Friday, so it's time for base and trim. I'd rather have the doors and door moulding in before installing the baseboard so I don't have to trim the baseboard later. Like a fucking idiot, I rock up to HD thinking I'm going home with some doors. Nooooope. If I want anything close to matching the rest of the house, it's make 'em myself or wait until June. Trying to decide how much more pain and suffering I'm into...YellowSnow said:

I’ve gotta interview GC’s this coming week. Worst year ever to remodel. Oh well.RaceBannon said:

Lot of truth hereRatherBeBrewing said:creepycoug said:

Bingo.RaceBannon said:No yard and 2 feet from your side neighbors

All the rage with the cost of development these days

I may be headed back to that area myself and looking for a little space. There are a lot of older places on nice lots. You can always fix up the house; you can't expand your lot (usually).

I’ve had to explain this concept to my significant other repeatedly. I’m not entirely against a subdivision but the newest ones are an exercise in how close and cheaply you can build houses and get away with it. She is starting to grasp that it may be better to get something non cookie cutter with a bit of space, and put some sweat equity into it.

We are in the market for an upgrade. Our current house is in the range of ones that shot up 20% in a quarter and are going like hot cakes the day they’re listed; the ones that are a step or two higher haven’t increased as much yet so I’m trying to strike while it makes sense.

It seems there are only three options:

1. Nice, newer houses with the accoutrements one expects: open floor plans, big kitchen, impressive master, walk-ins, bathrooms that don’t remind me of airplanes, etc.

Unless you hit the seven figure price point those will be built on a 7,000 SF lot and you can have a conversation with half of the neighborhood from your postage sized backyard.

2. A custom built from 1970-2000 something before the McMansion subdivision made that rare. It will be on primo land, instead of flat farm land that has been turned into a generic grid or something next to a busy four lane road.

The downside is that it will often be some crazy shit, most likely dated beyond hope and the architect who designed and drafted it with his own three hands was institutionalized for hearing voices.

Enjoy this three bedroom, eight bathroom, with staircases inspired by MC Escher! Features wine cellar that can be converted to a sex dungeon (or vice versa), three bars, dedicated RV parking for a 98 foot RV or a dirigible, dining room built in a Japanese style, the adjoining living room with a Southwestern flair and a fireplace made out of the bones of a now extinct wild horse! We suggest you learn to use the fireplace because this house uses more electricity than a small African nation. No windows on the north side of the house but there are impossible to replace skylights throughout. New owner assumes all responsibility, including possible haunting by malevolent spirits.

3. The “Grandma’s been put in the cheapest old folks home we could find and we’re splitting this jackpot seven ways” special.

House will look even worse because it’s filled with 1970s furniture, curtains, peeling linoleum, flowery wallpapers, the worst and shaggiest carpet you can imagine, toilets and baths will be pink. When this house was built it wasn’t allowed to have more than one small window per room, they will all be too high or too low to create the perfect atmosphere of mid century gloom. The kitchen is wide enough for one petite person to be in at a time.

I hope you really like oak or something that looks like oak! Because everything in this house looks like fucking oak. The window trim and sills, every door, every cabinet, maybe a wall or two. Everything is oak! Except for the floors, which are carcinogenic plastics.

The yard is the perfect size and will look great if it’s not neglected for another 30 years. When your neighbors are doing some domestic violence shit or yelling at their new puppy you won’t know because your $850k house isn’t three feet from theirs!

The problem is the shitty homes are overpriced limiting how much to light on fire remodeling it and still getting a return. If that matters which it usually does

You could take any house to the studs that is on a nice lot and build it back better (SWIDT). If you hire a good GC you can get it done fast. But its 100 grand easy. Or you could call @1to392831weretaken and spread it out over years of pain and suffering

As a contractor I always say there is nothing we can't do with your money

I like to say that -

We’re already planing for the delays and getting appliances ordered now. What a shit show. Liking the new Bosch dishwashers based on @BennyBeaver recommendation.1to392831weretaken said:

This for the kitchen? At least there's not a lot of lumber involved in that. The main problem with a lot of other materials isn't so much the cost but the wait. Eight weeks for a bathroom vanity. We got our bedroom carpet in Friday, so it's time for base and trim. I'd rather have the doors and door moulding in before installing the baseboard so I don't have to trim the baseboard later. Like a fucking idiot, I rock up to HD thinking I'm going home with some doors. Nooooope. If I want anything close to matching the rest of the house, it's make 'em myself or wait until June. Trying to decide how much more pain and suffering I'm into...YellowSnow said:

I’ve gotta interview GC’s this coming week. Worst year ever to remodel. Oh well.RaceBannon said:

Lot of truth hereRatherBeBrewing said:creepycoug said:

Bingo.RaceBannon said:No yard and 2 feet from your side neighbors

All the rage with the cost of development these days

I may be headed back to that area myself and looking for a little space. There are a lot of older places on nice lots. You can always fix up the house; you can't expand your lot (usually).

I’ve had to explain this concept to my significant other repeatedly. I’m not entirely against a subdivision but the newest ones are an exercise in how close and cheaply you can build houses and get away with it. She is starting to grasp that it may be better to get something non cookie cutter with a bit of space, and put some sweat equity into it.

We are in the market for an upgrade. Our current house is in the range of ones that shot up 20% in a quarter and are going like hot cakes the day they’re listed; the ones that are a step or two higher haven’t increased as much yet so I’m trying to strike while it makes sense.

It seems there are only three options:

1. Nice, newer houses with the accoutrements one expects: open floor plans, big kitchen, impressive master, walk-ins, bathrooms that don’t remind me of airplanes, etc.

Unless you hit the seven figure price point those will be built on a 7,000 SF lot and you can have a conversation with half of the neighborhood from your postage sized backyard.

2. A custom built from 1970-2000 something before the McMansion subdivision made that rare. It will be on primo land, instead of flat farm land that has been turned into a generic grid or something next to a busy four lane road.

The downside is that it will often be some crazy shit, most likely dated beyond hope and the architect who designed and drafted it with his own three hands was institutionalized for hearing voices.

Enjoy this three bedroom, eight bathroom, with staircases inspired by MC Escher! Features wine cellar that can be converted to a sex dungeon (or vice versa), three bars, dedicated RV parking for a 98 foot RV or a dirigible, dining room built in a Japanese style, the adjoining living room with a Southwestern flair and a fireplace made out of the bones of a now extinct wild horse! We suggest you learn to use the fireplace because this house uses more electricity than a small African nation. No windows on the north side of the house but there are impossible to replace skylights throughout. New owner assumes all responsibility, including possible haunting by malevolent spirits.

3. The “Grandma’s been put in the cheapest old folks home we could find and we’re splitting this jackpot seven ways” special.

House will look even worse because it’s filled with 1970s furniture, curtains, peeling linoleum, flowery wallpapers, the worst and shaggiest carpet you can imagine, toilets and baths will be pink. When this house was built it wasn’t allowed to have more than one small window per room, they will all be too high or too low to create the perfect atmosphere of mid century gloom. The kitchen is wide enough for one petite person to be in at a time.

I hope you really like oak or something that looks like oak! Because everything in this house looks like fucking oak. The window trim and sills, every door, every cabinet, maybe a wall or two. Everything is oak! Except for the floors, which are carcinogenic plastics.

The yard is the perfect size and will look great if it’s not neglected for another 30 years. When your neighbors are doing some domestic violence shit or yelling at their new puppy you won’t know because your $850k house isn’t three feet from theirs!

The problem is the shitty homes are overpriced limiting how much to light on fire remodeling it and still getting a return. If that matters which it usually does

You could take any house to the studs that is on a nice lot and build it back better (SWIDT). If you hire a good GC you can get it done fast. But its 100 grand easy. Or you could call @1to392831weretaken and spread it out over years of pain and suffering

As a contractor I always say there is nothing we can't do with your money

I like to say that -

This raises a great question. Probably not pole-worthy, and I've already jacked this thread so hard it'll be avoided like an AOG Central gamethread, so I'll just put it here:YellowSnow said:

We’re loving our .13 acre 2400 sq ft lifestyle. But that’s only cause our neighbors are great. I’d hate comparable density in Woodinville or most places.RaceBannon said:No yard and 2 feet from your side neighbors

All the rage with the cost of development these days

I work with a younger guy who bought his first house up in the sticks a few years back. Five acres, came with a tractor, old house, long commute. It was the compromise he had to make to be able to afford anything at the time. He's a hardworking, outdoorsy type who grew up on acreage and doing chores, so he thought that's the lifestyle he wanted for himself and his young family as well. Took three years (and two babies) of that shit, and he sold the place and moved into town and rents a house that sounds a lot like what @YellowSnow has going on. He was tired of spending all of his free time doing yardwork and fixing up an old house and was done with it.

I've wondered often lately if I made a similar mistake. I, too, grew up on acreage in the sticks, and my two years in the dorms were the only time in my life that I didn't have a lot of space and privacy. I thought having a big yard, trees to climb, chores to do, etc. would be good for kids, so a house with some property was what I sought out. It's always been a curious thing for me that these cookie cutter neighborhood houses sell for more than the houses in older neighborhoods where each house is different and lots are three times as big. I'm sure the houses being newer has something to do with it, but, from watching my friends go through the house-hunting process, I came to realize that it's also simply a product of demand: People want to live in neighborhoods. They want to have neighbors close by. I call it "the cul de sac life."

Three or four years ago, I finally understood why. Lack of property upkeep aside, the thing I started to envy about my friends' cul de sac life was that we were always having to drive our kids around to visit their friends. Or people would have to drive their kids here, so it happened a lot more rarely. My friends? They'd just push their kid out the door. Every time I'd drop off my son or daughter, there'd be a gang of little kids playing together in the cul de sac. I wondered for a long time if my choice of more "rural" living was disadvantaging my kids--socially, athletically, etc. I don't know. If you're raising young kids, there's definitely an appeal to being surrounded in walking distance by a ton of other families with kids for yours to play with.

Nowadays, not such a big deal. The kids are old enough to bike or walk to several friends in each direction, and they are constantly doing so. Moreover, their friends can easily come here, and our place is finally paying off as the sweet hangout. COVID turned the shop into the epicenter of elementary school activity this year, as having an 18' door rolled up was an acceptable compromise on shitty days for "playing outside" for most of the neighborhood parents. That, and having a dirt bike track in the backyard is finally something that the other kids think is cool. So not uncommon for there to be anywhere from six to eight kids at my place three or four days per week since last April.

Still, I think new(er) house, .13 acres, cool neighbors is a pretty sweet recipe for raising young kids, and I still have some regrets. -

We very much have the cool neighbors cul de sac lifestyle. There’s like 8 little boys the same age as our oldest with 100 yds. It looks like something out of a Norman Rockwell painting and will limit TV and video games. Kids still like playing outside over anything else.1to392831weretaken said:

This raises a great question. Probably not pole-worthy, and I've already jacked this thread so hard it'll be avoided like an AOG Central gamethread, so I'll just put it here:YellowSnow said:

We’re loving our .13 acre 2400 sq ft lifestyle. But that’s only cause our neighbors are great. I’d hate comparable density in Woodinville or most places.RaceBannon said:No yard and 2 feet from your side neighbors

All the rage with the cost of development these days

I work with a younger guy who bought his first house up in the sticks a few years back. Five acres, came with a tractor, old house, long commute. It was the compromise he had to make to be able to afford anything at the time. He's a hardworking, outdoorsy type who grew up on acreage and doing chores, so he thought that's the lifestyle he wanted for himself and his young family as well. Took three years (and two babies) of that shit, and he sold the place and moved into town and rents a house that sounds a lot like what @YellowSnow has going on. He was tired of spending all of his free time doing yardwork and fixing up an old house and was done with it.

I've wondered often lately if I made a similar mistake. I, too, grew up on acreage in the sticks, and my two years in the dorms were the only time in my life that I didn't have a lot of space and privacy. I thought having a big yard, trees to climb, chores to do, etc. would be good for kids, so a house with some property was what I sought out. It's always been a curious thing for me that these cookie cutter neighborhood houses sell for more than the houses in older neighborhoods where each house is different and lots are three times as big. I'm sure the houses being newer has something to do with it, but, from watching my friends go through the house-hunting process, I came to realize that it's also simply a product of demand: People want to live in neighborhoods. They want to have neighbors close by. I call it "the cul de sac life."

Three or four years ago, I finally understood why. Lack of property upkeep aside, the thing I started to envy about my friends' cul de sac life was that we were always having to drive our kids around to visit their friends. Or people would have to drive their kids here, so it happened a lot more rarely. My friends? They'd just push their kid out the door. Every time I'd drop off my son or daughter, there'd be a gang of little kids playing together in the cul de sac. I wondered for a long time if my choice of more "rural" living was disadvantaging my kids--socially, athletically, etc. I don't know. If you're raising young kids, there's definitely an appeal to being surrounded in walking distance by a ton of other families with kids for yours to play with.

Nowadays, not such a big deal. The kids are old enough to bike or walk to several friends in each direction, and they are constantly doing so. Moreover, their friends can easily come here, and our place is finally paying off as the sweet hangout. COVID turned the shop into the epicenter of elementary school activity this year, as having an 18' door rolled up was an acceptable compromise on shitty days for "playing outside" for most of the neighborhood parents. That, and having a dirt bike track in the backyard is finally something that the other kids think is cool. So not uncommon for there to be anywhere from six to eight kids at my place three or four days per week since last April.

Still, I think new(er) house, .13 acres, cool neighbors is a pretty sweet recipe for raising young kids, and I still have some regrets.

The price point is such that there’s no riff raff to be pain in the ass neighbors. -

@YellowSnow:

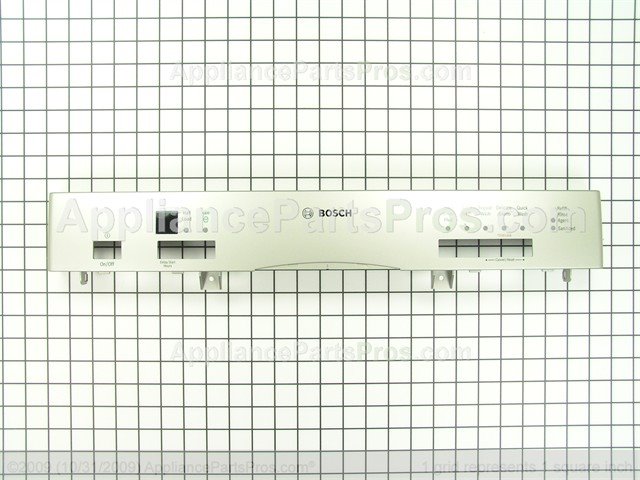

I am on my second Bosch dishwasher. As far as doing their jerb, they're great. HOWEVER... I'm about to be on my third Bosch dishwasher. A few months ago, my wife opened the door to unload, and the handle ripped right off. Turns out it's just a thin piece of injection molded ABS (or painted ABS if you get the stainless version) that's screwed into the top of the door panel. It's held on by a whopping four tabs. The shittiness of this design absolutely blows me away. As in, this part breaking off wasn't a one-off, it was inevitable eventually. Because our appliances are black, which is now totally out of style, it takes even longer to get replacements. We've debated just biting the bullet and swapping all of them out just so we don't run into the problem of not being able to find replacements, but we're too cheap/stupid to do so (replacing the refrigerator last April was suuuuuper fun...). Anyway, in order to avoid being without a dishwasher for the three or four months it would probably take to get a replacement, I plastic-welded the trim piece with the built-in handle back together and buffed it out as best I could. Half the locking tabs are still missing, so it's super ghetto, but it still does the job, and nobody visiting can tell it's broken. Pisses me right the fuck off, though. I believe it's only two or three years old.

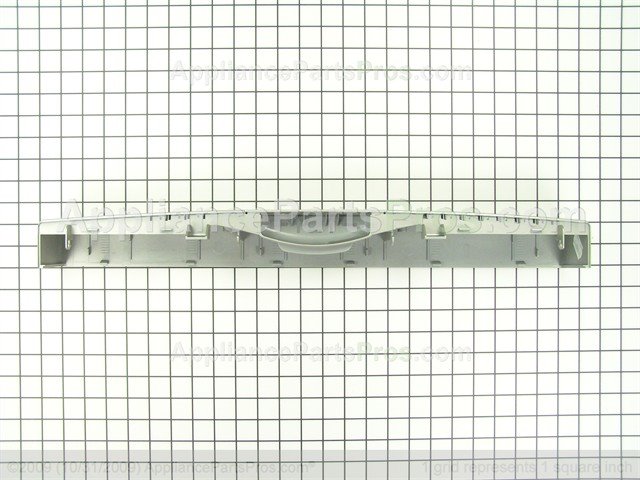

Here's a similar part for a different model, but it attaches the same way:

You can see the four bigger tabs that screw this piece on. They're flimsy as fuck and barely reinforced. All four snapped, cracking the face of the fascia piece. I was at least able to weld these tabs back on. What I couldn't fix is those six little tabs on the top side that hook it into the main door panel. Those are tiny. So most of them also snapped off, hence this fascia panel feeling like it's going to tear off every time you open the door now. I need to get off my ass and just buy a replacement part or new dishwasher. I'm stubborn and too pissed off for that just yet, though.

Point is, it looks like this is a pretty standard design feature for many if not all of their models, as it was actually hard to find a replacement part for mine because I was wading through dozens and dozens of similar shitty flimsy ABS integrated fascia/handles from other models. If you're going to go Bosch, watch our for this. The handle should be metal, and it should be separate from the plastic fascia. -

Bosch dishwasher fupdate: I was just in HD getting bent over/no lube for some doors and trim, so I thought I'd head over to the dishwashers and check out what's going on these days.

There were only three dishwashers there that were Bosch. The handles are still molded into plastic fascia pieces, but they seem to wrap around better and be more supported. It still flexes and feels cheap, but seems superficially like it at least wouldn't break.

I know it's not cool looking to have a metal handle that protrudes from the front, but I might go that route next time to avoid breakage. -

Horton is shit. The only way to get something that isn’t builders grade is a custom home builder. Too rich for my pour ass.

Probably with selling right now is you have to buy in the same market. An almost identical home adjacent from us went for 65k more than we paid less then a yr ago. Side note, dude that bought it just came from Tacoma and is super happy about how much house he got for a third of WA housing prices. He also brews... 4 kinds on tap but I digress.

TOF and I are seriously thinking about selling because we could get at least 10k more if not closer to 20k. Then rent until I find my next promotion because we’re not staying here. Save $500 a month so 6k a yr back into retirement.

My point, unless you’re downgrading, moving to an area where you’re dollar gets you more, or finding a fixer upper, you’re SOL. -

You're not wrong at all, but what I've been cautioning is that fixering uppering is a lot more expensive these days than it used to be. Definitely have your ducks in a row and make sure you've checked your math if your strategy to get ahead in RE investment involves building materials and subcontractors. Depending on where you're located, it might not be worth it. There were temporary shortages in building materials due to COVID (they're WELL stocked now, but the price is still climbing, hence my concern that this is just the new reality now that they know they can get away with it), but a lot of it has to be demand driven due to lack of inventory on the RE market. When there's no house to move up to, everyone at once is having a go at improving the one they're in or building new, and this has made it a free for all in the construction trades.dirtysouwfdawg said:Horton is shit. The only way to get something that isn’t builders grade is a custom home builder. Too rich for my pour ass.

Probably with selling right now is you have to buy in the same market. An almost identical home adjacent from us went for 65k more than we paid less then a yr ago. Side note, dude that bought it just came from Tacoma and is super happy about how much house he got for a third of WA housing prices. He also brews... 4 kinds on tap but I digress.

TOF and I are seriously thinking about selling because we could get at least 10k more if not closer to 20k. Then rent until I find my next promotion because we’re not staying here. Save $500 a month so 6k a yr back into retirement.

My point, unless you’re downgrading, moving to an area where you’re dollar gets you more, or finding a fixer upper, you’re SOL. -

You nailed it - The cost of materials due to supply and demand is pricing a lot of people out of new builds making existing homes that much more coveted and driving those costs to some stupid numbers.

The sign in front of our neighborhood, mentioning homes starting at $$, has changed since covid and now shows a 75k increase compared to this time LY.

Yet, they are almost sold out of lots and are currently working on 4 homes. Riches going to rich... bigger and newer homes in the back half of the neighborhood.